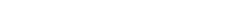

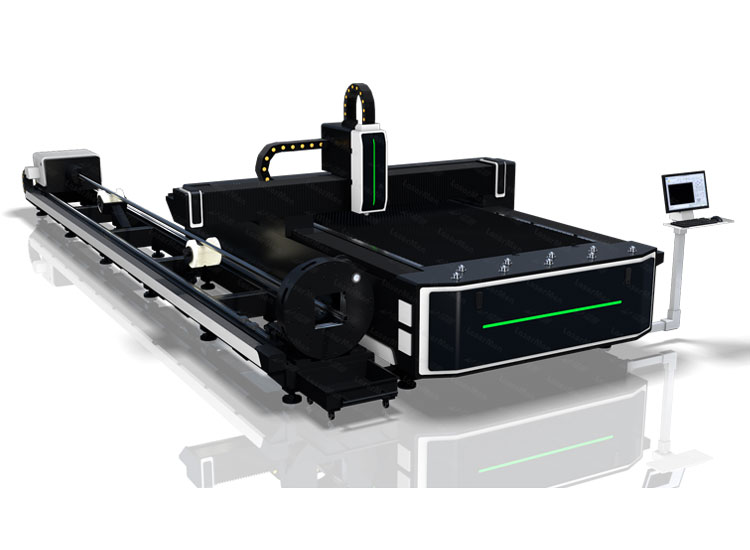

Machine features

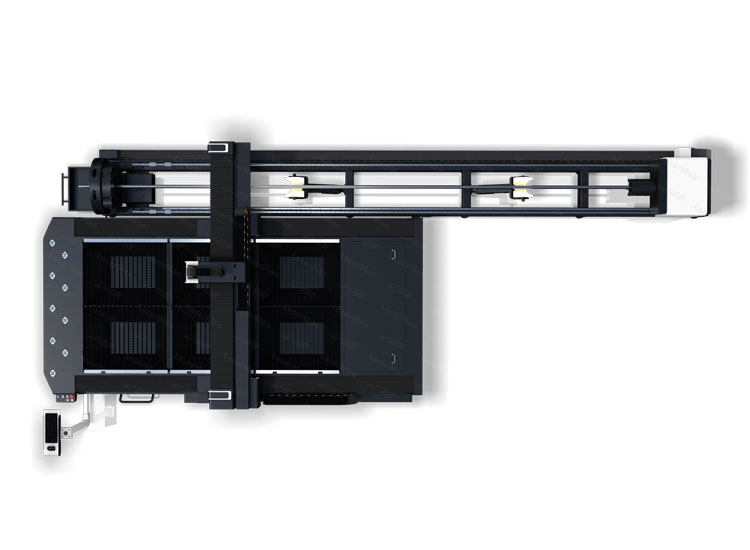

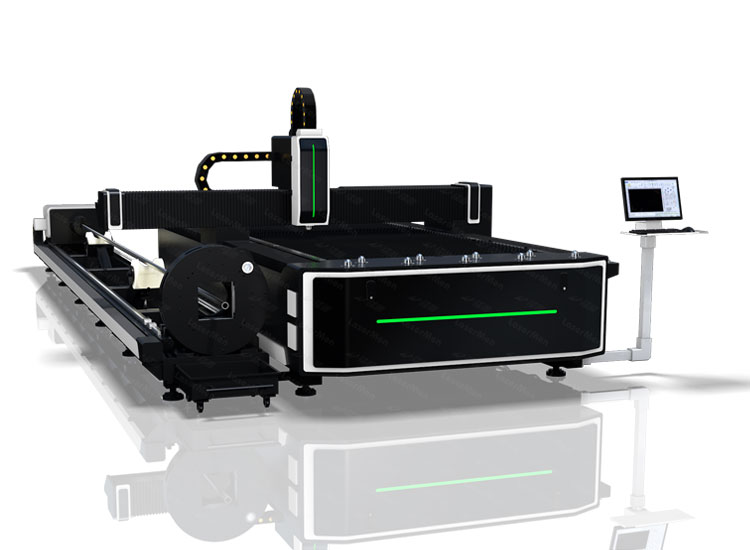

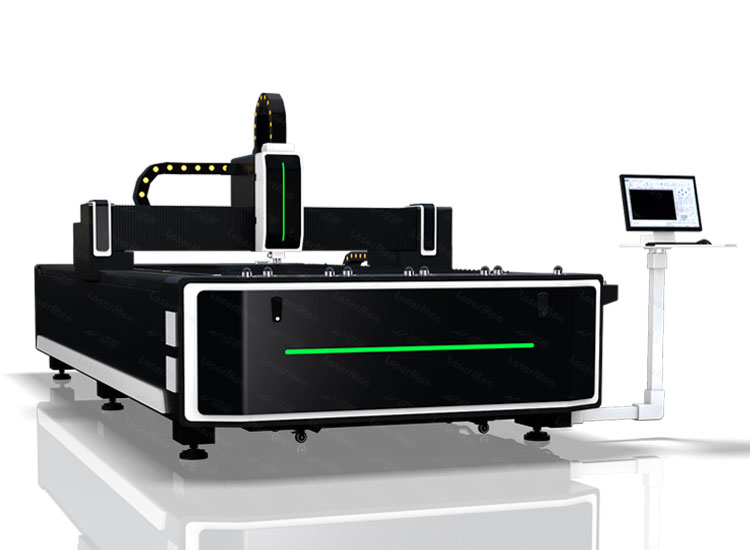

1. One machine has double function, cutting metal sheet and tube2. Cost-saving and high performance working, it has many uses and can save the space of more than 50%, which effectively improve productivity

3. Machine adopts FSCUT control system, two software (CYPCUT software for metal sheet cutting, Tubepro software for metal tube cutting)

4. The Rotary device can hold up maximum 220mm diameter metal tube, standard tube length is 3 meters or 6 meters, other length also can be customized

Technical parameters

| Model | LM-1530AFT / LM-1530BFT |

| Laser type | Fiber laser, 1080nm |

| Laser power | 1500W, 2000W, 3000W, 4000W, 6000W, 8000w |

| Working area | Sheet: 1500mm x 3000mm Tube:220mm diameter x 3 meters or 6 meters length |

| Min Line width | 0.1mm |

| Positioning accuracy | 0.01mm |

| Max. Cutting speed | 60m/min |

| Max acceleration | 1.5G |

| Transmission type | Precision dual gear rack transmission |

| Driving system | Serve motors |

| Cutting thickness | Depending on laser power and material |

| Assisting gas | Compressed air, oxygen and nitrogen |

| Cooling mode | Industrial circulation water chiller |

| Visual positioning | Red dot |

| Machine weight | Net 4500kgs |

| Working voltage | 3 phase 380V 50HZ/60HZ |

Video

Machine details

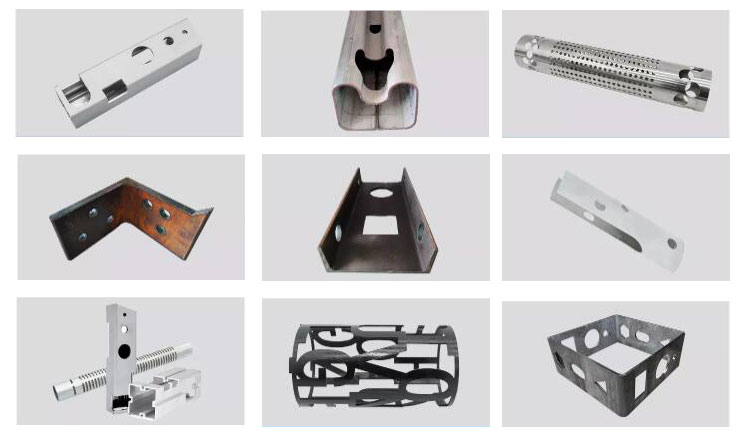

Machine Application

Application Materials:Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet ect.

Application Industries:

CNC Fiber Laser Cutting Machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.