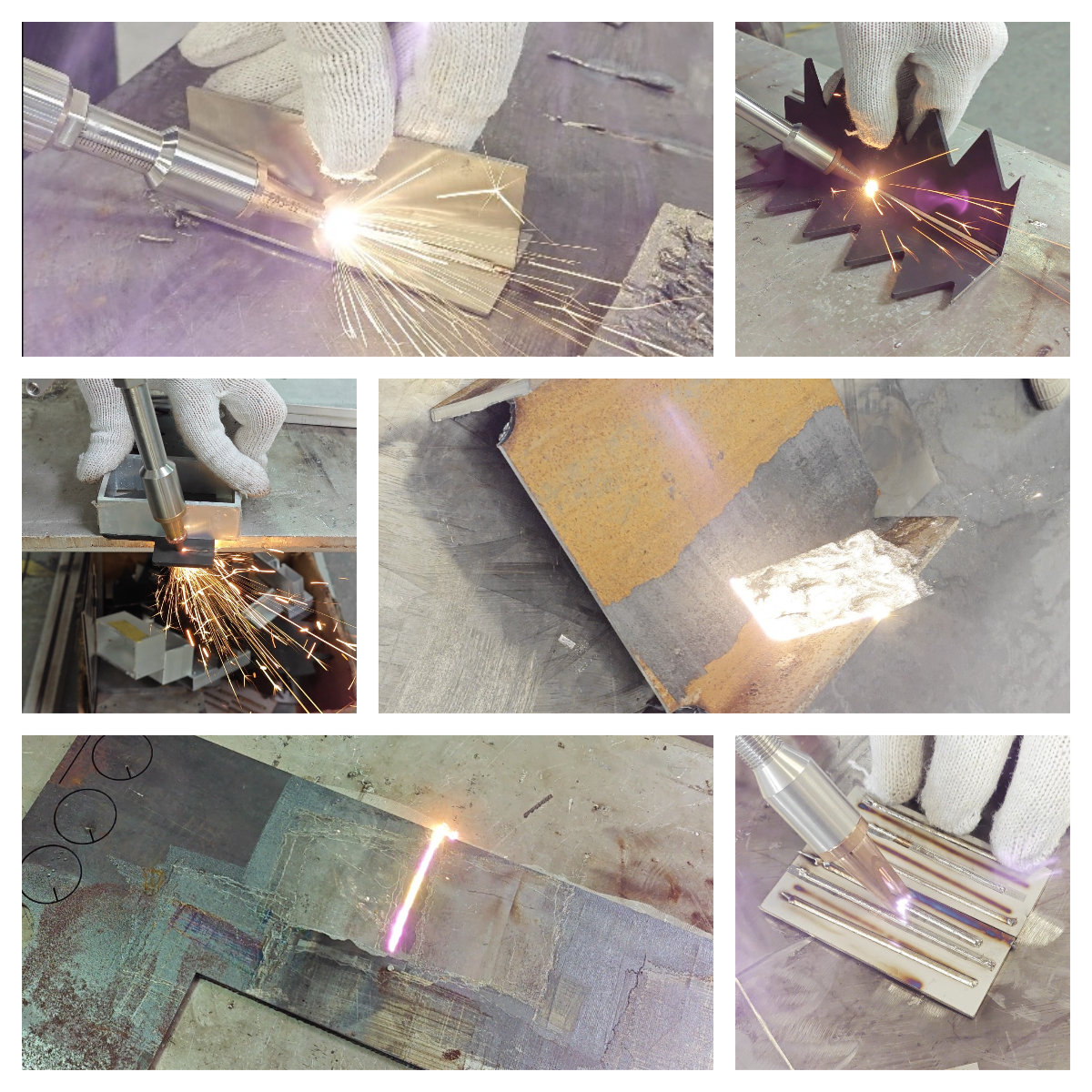

Modern laser welders, including fiber laser welding machines, portable laser welding machines, laser cutting and welding machines, and multifunctional 5 in 1 handheld laser welding machines, are widely used in metal fabrication, manufacturing, automotive repair, and aluminum processing. With optional laser sources such as Raycus, Maxphotonics, BWT, and JPT, our welding systems deliver stable, powerful, and high-precision performance for both industrial and commercial applications.

A laser welding machine uses a high-energy, concentrated laser beam to heat and melt metals at the welding joint. The melted material fuses together and forms a smooth, strong weld after cooling. This principle applies to all types of equipment, including the handheld laser welder, 4 in 1 portable laser welder, mini laser welding machine, and laser welding machine for metal.

Working Process:

Laser Generation

The machine uses a high-performance fiber source (Raycus, Maxphotonics, BWT, or JPT) to produce a stable, intense laser beam.

Beam Transmission

The beam is delivered through fiber optics to the welding torch for precise output.

Metal Fusion

The focused laser instantly melts the metal surface, forming a molten pool.

Solidification

The molten pool cools and solidifies into a uniform, beautiful, and durable weld seam with minimal distortion.

This working principle makes a laser welder machine excellent for stainless steel, carbon steel, galvanized plate, copper, and welding machine aluminum applications.

Advantages of Our Laser Welding Machines

1. Laser Power 1–3KW: Ideal for Welding Up to 10mm Metal

High-power fiber lasers can weld stainless steel, mild steel, and aluminum with thicknesses up to 10mm, making the system suitable for both industrial and daily fabrication tasks.

2. Strong, Clean, and Solid Welding Quality

The powerful beam of the fiber laser welding machine melts metals instantly, producing welds with:

No holes

No cracks

No deformation

Very strong bonding strength

This makes laser welding significantly superior to TIG/MIG for many metalworking operations.

3. Cleaning Mode for Rust, Paint, and Oxidation Removal

The laser beam impacts the metal surface at high energy, instantly gasifying rust, paint, oil, and oxidized layers.

This function is perfectly integrated into our laser cutting and welding machine, handheld laser welder, and 4 in 1 portable laser welder.

4. Lower Cost and Better Efficiency for Power Battery Welding

Laser welding is highly suitable for power battery welding due to:

High precision

Low heat input

Minimal spatter

Lower labor and consumable cost

This makes laser welding more economical than traditional battery welding processes.

5. Easy to Learn — Master in One Week

5. Easy to Learn — Master in One Week

New operators can learn to use the portable laser welding machine or mini laser welding machine in about one week.

This reduces labor requirements and helps companies save long-term operational costs.

6. Safety Guaranteed (CE Certified, Safety Goggles Included)

Our laser welding machines comply with CE standards and include professional laser safety goggles.

This ensures safe operation even for new users in manufacturing environments.

5-in-1 Multifunctional Operation (Flexible Working Modes)

Our 5 in 1 handheld laser welding machine supports five working modes:

Industrial Welding

For stainless steel, carbon steel, iron, copper, and aluminum.

Power Battery Welding

High-speed, precise joining of battery cases and tabs.

Rust Removal / Cleaning Mode

Removes rust, oil, paint, and oxide layers on metal surfaces.

Weld Seam Cleaning

Cleans discoloration and oxide residue after welding.

Laser Cutting Mode

Supports cutting thin metal plates with clean edges.

These five modes make the machine a true all-in-one solution and significantly improve workshop efficiency.

Optional Laser Sources: Raycus, Maxphotonics, BWT, JPT

We offer four high-quality, customizable laser sources:

Raycus – Stable beam, high energy density, excellent for industrial welding

Maxphotonics – Strong penetration and reliable output

BWT – High durability and long service life

JPT – Precise control and smooth welding performance

These sources ensure stable results regardless of whether you use a laser welding machine for metal, laser welder machine, or portable laser welding machine.

Conclusion

Whether you choose a fiber laser welding machine, portable laser welding machine, handheld laser welder, 4 in 1 portable laser welder, or laser cutting and welding machine, laser welding provides unmatched precision, speed, and efficiency.

With optional Raycus, Maxphotonics, BWT, and JPT laser sources, our equipment can meet the demands of industrial welding, aluminum fabrication, power battery manufacturing, cleaning, and cutting—all in one powerful and user-friendly machine.

Laser welding is the future of metal processing: faster, cleaner, stronger, and more economical.