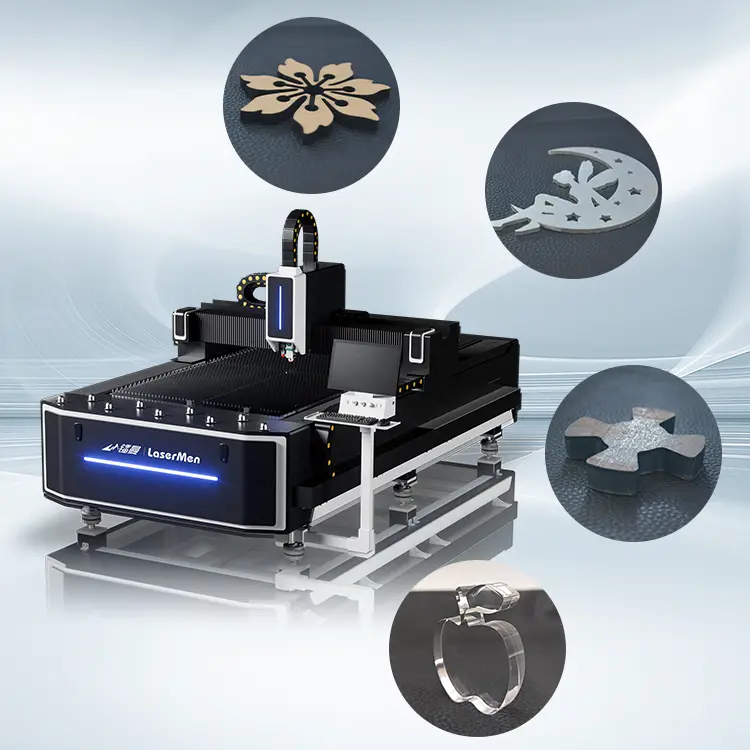

A fiber and CO2 laser cutting machine combo integrates two laser technologies into a single platform, giving manufacturers unmatched flexibility without sacrificing performance.

Limitations of Single-Laser Machines

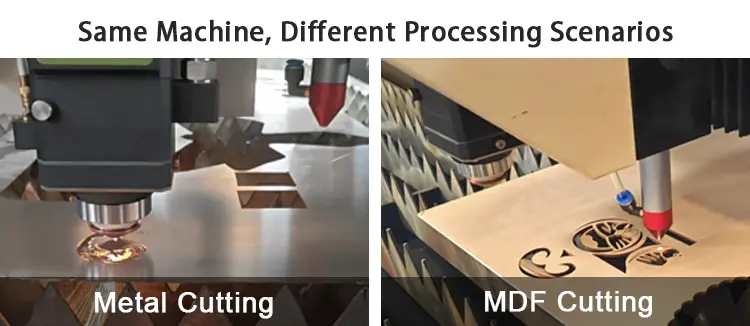

A traditional CO2 laser cutting machine performs well on acrylic, MDF and other non-metal materials, but its efficiency and cutting speed on metal are limited. Thin sheet metal cutting is possible, yet it cannot match the speed, precision or energy efficiency of fiber laser technology.

On the other hand, a fiber laser cutting machine is ideal for metal processing. It easily handles stainless steel, carbon steel and aluminum, including common applications such as 3mm sheet metal laser cutting. However, fiber lasers are not suitable for transparent or organic materials like acrylic and wood, which restricts their application range.

For users working with mixed materials, choosing only one technology often means compromise—or the cost of purchasing two separate machines.

The Advantage of Dual-Laser Technology

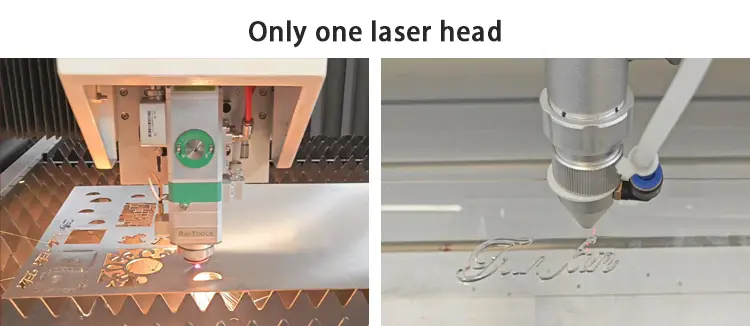

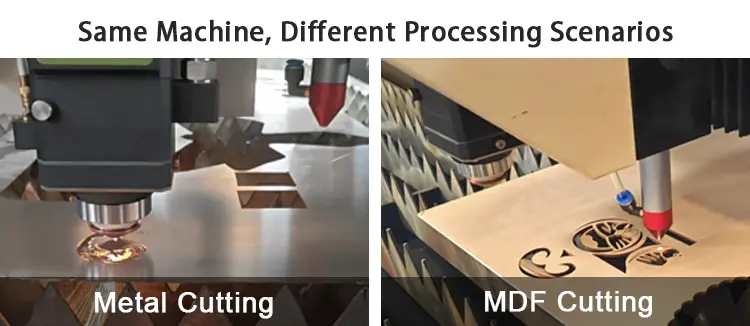

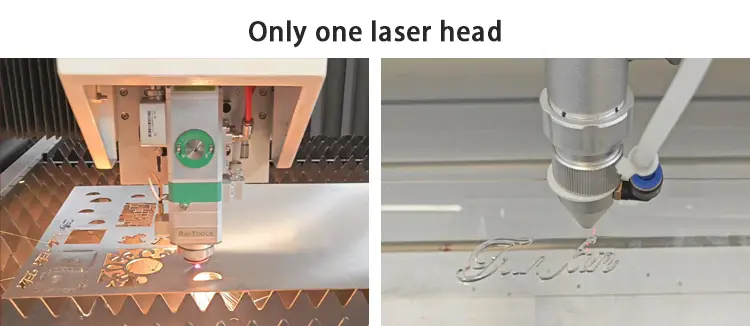

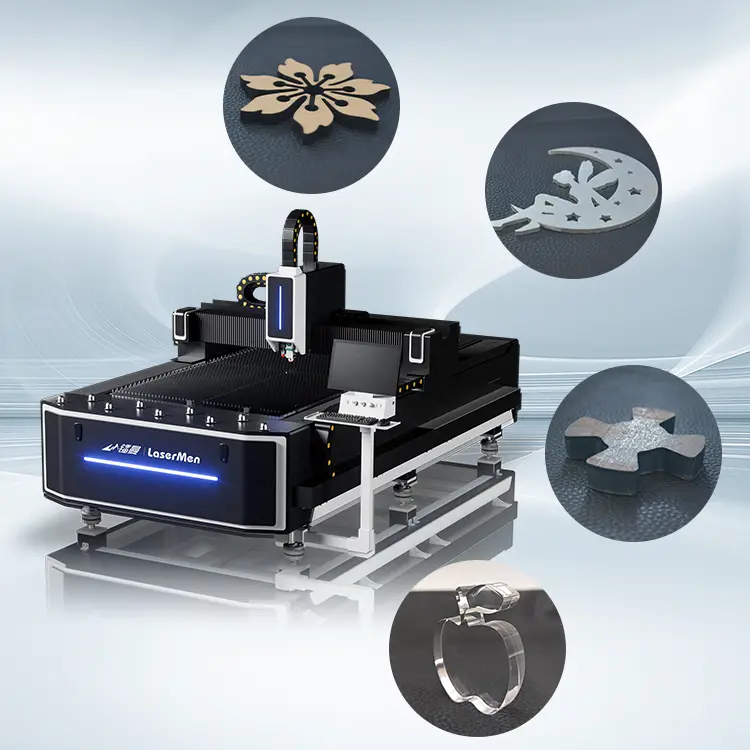

A dual-laser system combines the strengths of both technologies in one compact solution. The fiber laser module is dedicated to metal cutting, delivering high efficiency, clean edges and stable performance, even when configured as a 1.5KW fiber laser cutting machine for aluminum and thin steel sheets.

At the same time, the CO2 laser handles non-metal materials with ease, producing smooth, polished edges on acrylic and consistent results when cutting MDF or other decorative materials. This makes the system suitable for both industrial metal processing and creative or advertising applications.

Instead of switching machines or outsourcing jobs, users can complete metal and non-metal orders on the same platform, improving workflow efficiency and reducing production downtime.

Lower Cost, Higher Utilization

Compared with buying separate machines, a fiber and CO₂ laser cutting machine significantly reduces equipment investment, factory space requirements and operating costs. One operator, one control system and one working area can cover multiple production needs.

For small factories, job shops and manufacturers seeking versatility, this dual-laser solution offers a faster return on investment and greater long-term flexibility.

One Machine, More Possibilities

If your business requires both metal cutting and non-metal processing, a dual-laser system is not just a compromise—it is an upgrade.

By combining fiber laser power with CO₂ laser precision, this new generation of laser cutting machines opens the door to broader applications, higher efficiency and smarter production planning.

Products you might be interested in:

https://www.lasermencnc.com/multi-functional-laser-system/

https://www.lasermencnc.com/datail_51_113.html

https://www.lasermencnc.com/datail_51_93.html

https://www.lasermencnc.com/datail_51_102.html

https://www.lasermencnc.com/datail_51_85.html