If you're looking for a smarter way to scale, it’s time to rethink your setup.

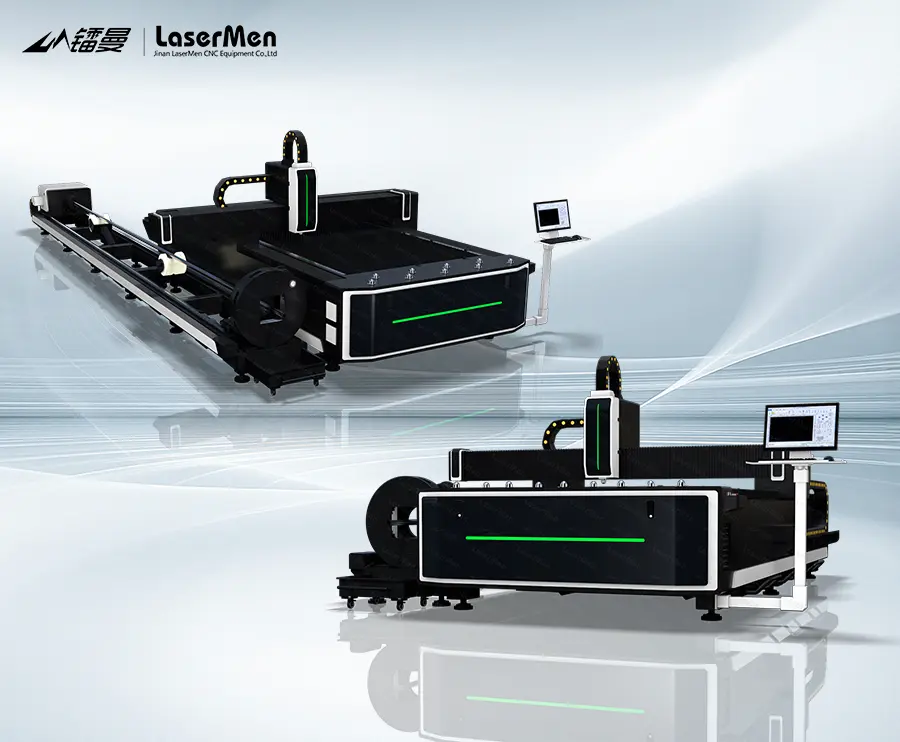

One Platform. Complete Metal Processing.

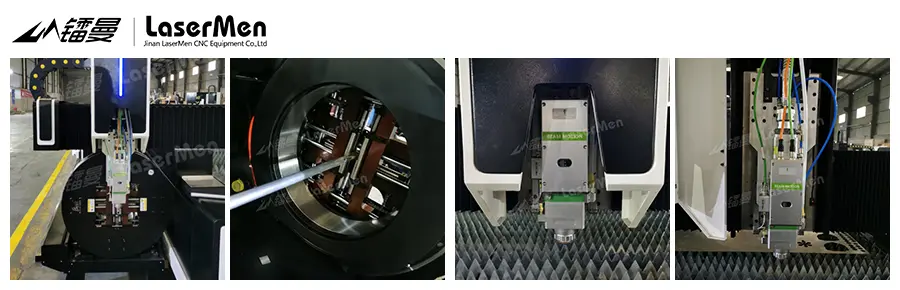

LM-1530AFT sheet and tube laser cutting machine combines flat sheet processing (3000×1500mm) with an integrated rotary unit for tubes up to 220mm diameter.

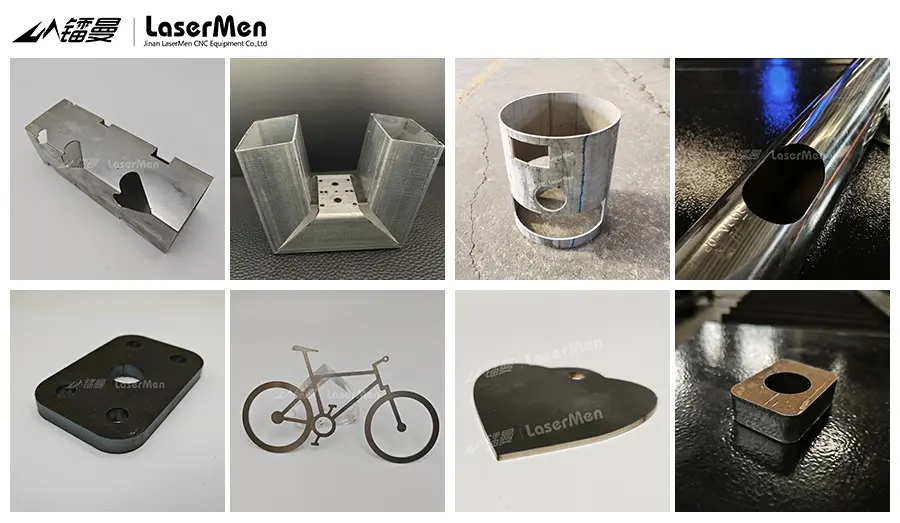

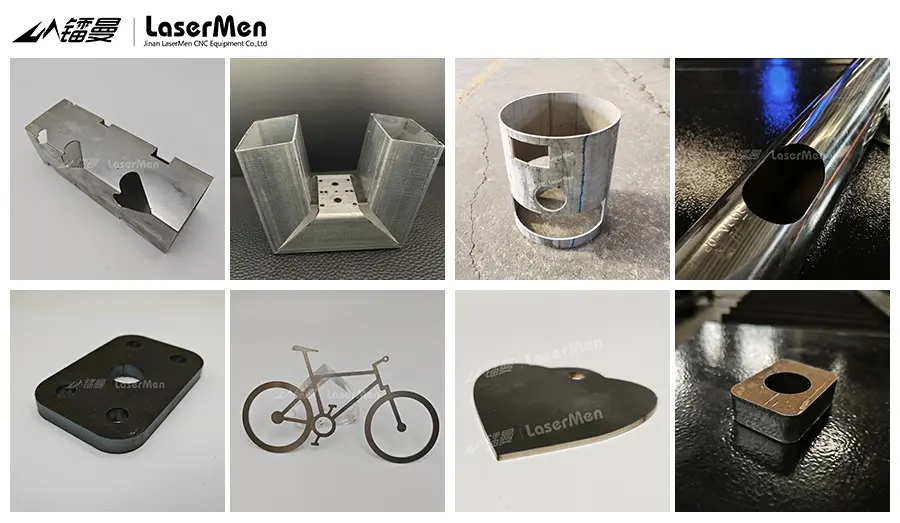

Instead of investing in separate systems, this plate and tube integrated laser cutting machine allows manufacturers to process:

Stainless steel sheets

Carbon steel plates

Aluminum and brass panels

Round, square, and irregular metal tubes

All within one intelligent platform.

Power Options for Real Industrial Demands

Available in 1500W, 2000W and 3000W configurations, this machine adapts to different production volumes.

For example:

A 1500W fiber laser system handles thin stainless steel efficiently

A 2000W setup increases speed for medium thickness materials

The 3000W model supports heavier industrial workloads

Whether you need a high precision metal solution or higher throughput, LM-1530AFT delivers stable and consistent performance.

Designed for Modern Fabrication Workshops

This model is widely used in:

Sheet metal fabrication

Automotive component production

Elevator panel manufacturing

Advertising signage and metal letters

Furniture frames and structural parts

As a professional CNC tube processing system, it supports 3m and 6m tube lengths, meeting real factory production requirements.

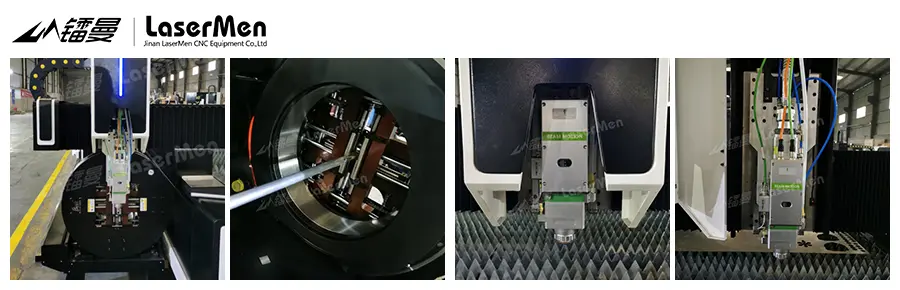

Intelligent Control, Simplified Operation

Equipped with FSCUT control technology and dual software integration, the machine enables smooth switching between sheet and pipe modes.

Fiber transmission reduces maintenance needs while improving energy efficiency compared to traditional CO2 systems.

For manufacturers upgrading from conventional metal equipment, this modern system offers better speed, lower operating costs, and long-term reliability.

Ready to Upgrade?

If your factory is expanding production or replacing older equipment, the LM-1530AFT offers:

Space-saving design

Multi-function capability

Industrial-level stability

Flexible power selection

Contact LaserMen today for technical details, cutting samples, and a customized quotation.

Let’s build a smarter metal processing line together.