Posted on January 13th, 2026 · By Lasermencnc · In Laser Machines Blog · 5 Min Read

For small and medium-sized manufacturing enterprises, maker spaces, and advertising processing plants, there are often two difficulties when purchasing laser equipment. Buying metal laser cutters, non-metal engraving machines, and laser welding machines separately not only incurs high initial investment costs but also takes up a large amount of factory space. On the other hand, purchasing only single-function equipment fails to meet the production needs for multiple materials and processes. The LM-1390-WFC multi-functional laser processing system launched by Jinan LaserMen CNC in 2025, with its "10-in-1" full-scenario coverage capability, has become a cost-effective choice to address this pain point. This article will help you comprehensively understand this equipment from four dimensions: model selection logic, technical analysis, industry applications, and common problems, so as to accurately match your production requirements. Webpage for the detailed functions, applications and parameters of this product: https://www.lasermencnc.com/multi-functional-laser-system/

Before you go out and buy laser processing gear, it’s smart for businesses to nail down exactly what they need for production first. That way, you won’t end up following trends blindly or paying for features you’ll never use.

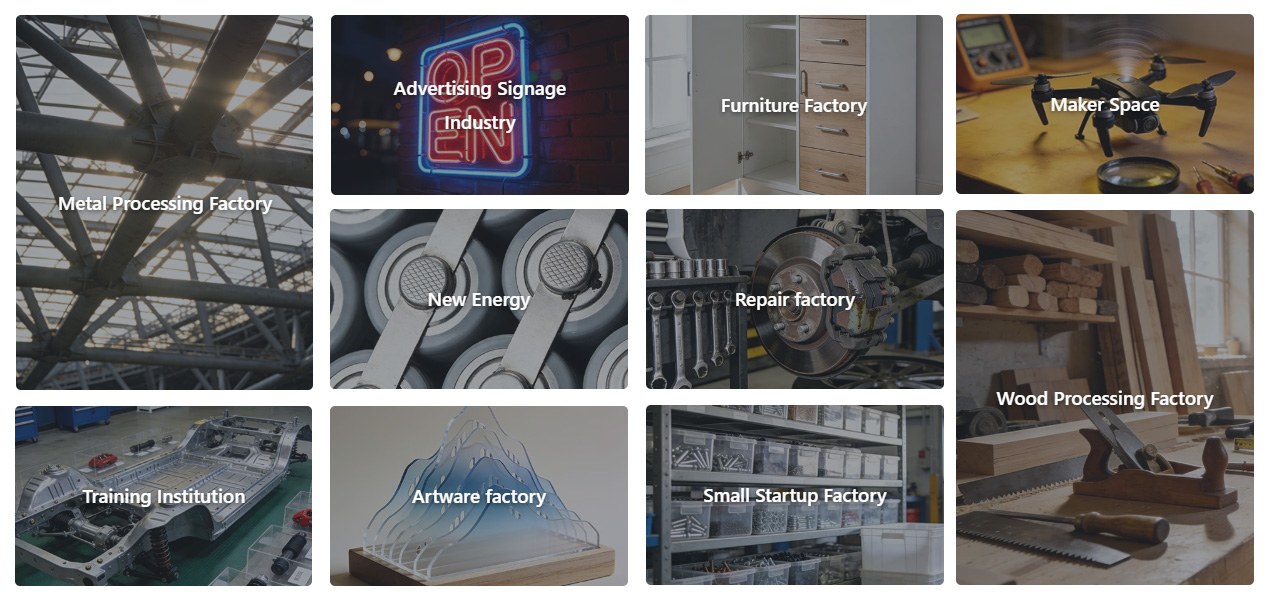

Applicable Scenarios:

Inapplicable Scenarios:

| Comparison Dimension | 10-in-1 Multi-Functional Laser System | Combination of Single-Function Laser Equipment (Cutting + Engraving + Welding) |

|---|---|---|

| Initial Investment | About 60%-70% of the combined equipment | High total equipment price and large investment cost |

| Floor Area | Only 2.38×1.7×1.1m is needed, saving 70% of space | Need to place multiple devices separately, occupying a large space |

| Operation Difficulty | Unified control system, easy to get started, operable by 1 person | Need to be familiar with the operation logic of multiple devices, high training cost |

| Maintenance Cost | Centralized maintenance, convenient replacement of consumables, low cost | Multiple devices need to be maintained separately, with many types of consumables and high cost |

| Processing Efficiency | No need to change equipment for multi-process switching, saving line change time | Different processes require changing equipment for processing, low switching efficiency |

| Applicable Scale | Small and medium batch, multi-variety production | Mass production, single variety production |

From the perspective of long-term use cost, the multi-functional laser system can save 30%-40% of the comprehensive cost for small and micro enterprises, especially suitable for the production mode of multi-variety and small-batch.

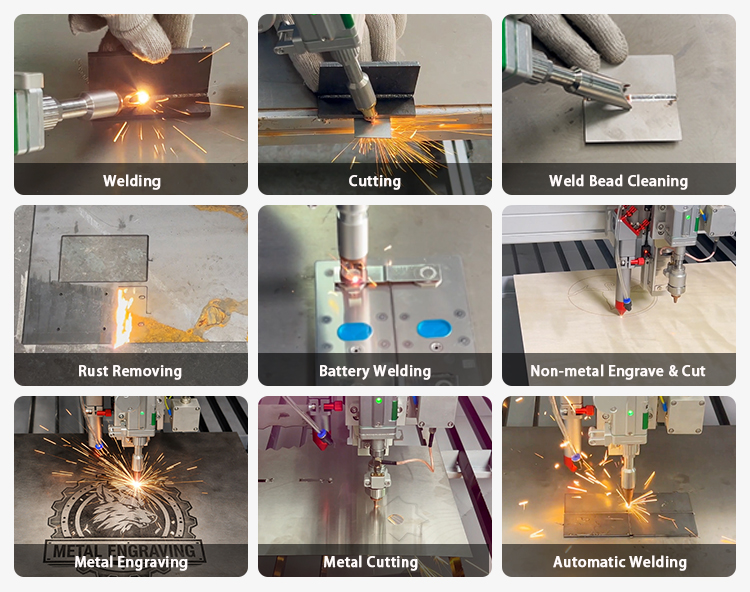

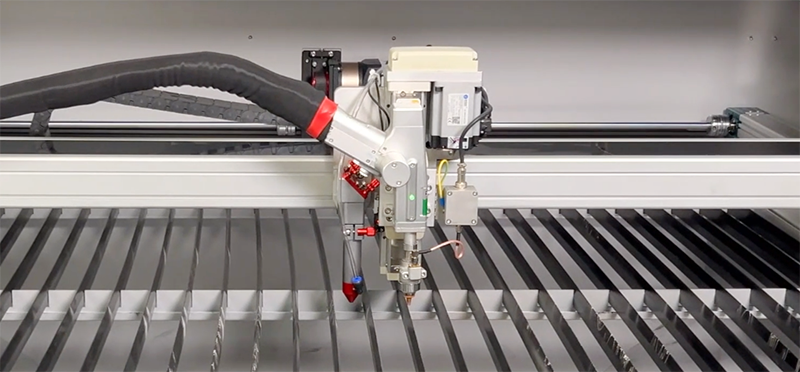

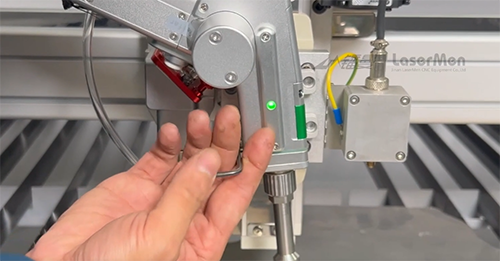

Return to Table of ContentsThe LM-1390-WFC multi-functional laser processing system integrates fiber laser and CO2 laser technology, realizing independent operation of 10 core functions to meet different processing needs:

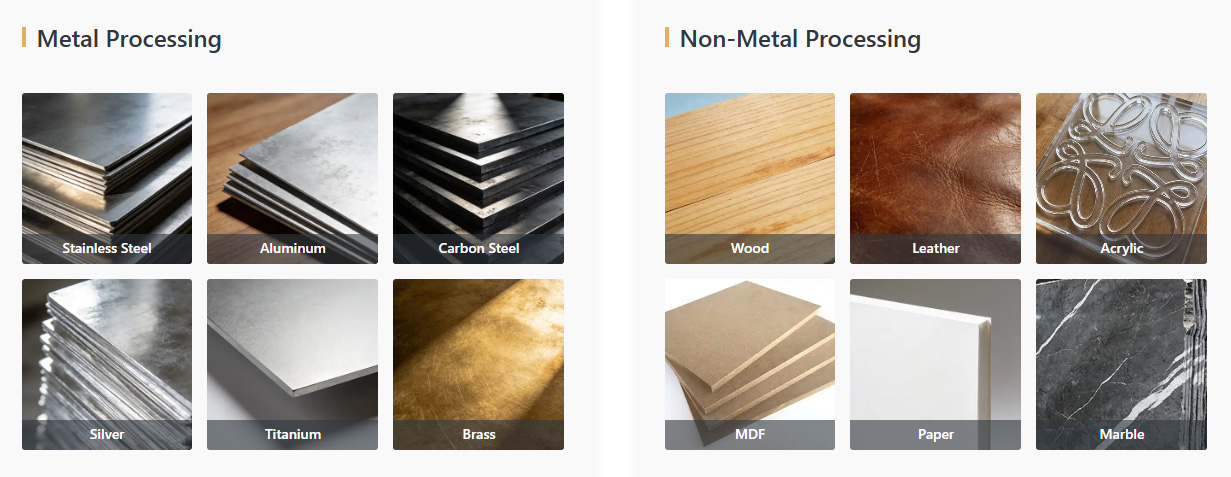

Metal Processing Functions (5 items):

Non-Metal Processing Functions (5 items):

The technical parameters of the equipment directly determine the processing effect and production efficiency. The following is an analysis of the key parameters of the LM-1390-WFC. All parameters are in line with actual production needs, balancing performance and practicality:

| Parameter Category | Specific Specifications | Practical Application Value |

|---|---|---|

| Processing Area | CNC laser processing area: 1300×900mm; Handheld processing area: 9m laser head cable | Meet batch processing of small and medium-sized workpieces, handheld mode can handle local processing of large workpieces |

| Laser Power | Fiber laser 1500W; CO2 laser 130W | Fiber laser is suitable for metal processing, CO2 laser is suitable for non-metal processing, and power matching balances efficiency and precision |

| Positioning Accuracy | ±0.01mm, repeat positioning accuracy ≤0.01mm | Ensure the consistency of batch processing, suitable for high-precision product production |

| Running Speed | Maximum running speed 35m/min, acceleration 0.25G | Improve processing efficiency and shorten the processing time of single product |

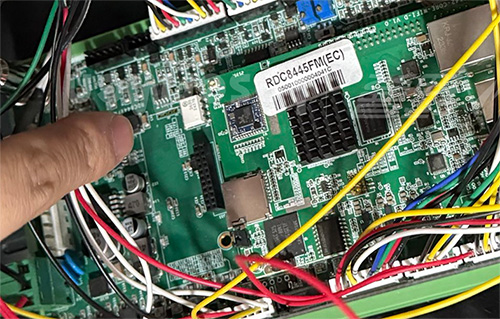

| Control Method | Offline control | Can run without connecting to a computer, reduce equipment occupation space, and operate more conveniently |

| Power Supply Requirements | Single-phase 220V 50/60Hz | No need for special industrial three-phase electricity, ordinary factory circuits can meet the requirements, reducing installation costs |

| Equipment Weight and Dimensions | Weight 750kg; Dimensions 2380×1700×1100mm | Moderate weight for easy installation and commissioning, compact design saves factory space |

Previously, an advertising processing factory needed 3 devices: acrylic cutting machine, metal letter engraving machine, and wooden display board engraving machine, which not only occupied 30㎡ of factory space but also required 2 operators. After purchasing the LM-1390-WFC, the following changes were achieved:

A small new energy battery production enterprise needs to handle processes such as battery shell derusting, electrode welding, shell cutting, and weld cleaning. After using the multi-functional laser system:

A maker laboratory of a vocational and technical college needs to meet the teaching needs of multiple majors such as mechanical design, advertising design, and industrial design. After introducing this multi-functional equipment:

A small and medium-sized furniture factory focuses on the production of customized wooden furniture and metal accessories, and previously faced the dilemma of "small-batch orders are not cost-effective, and large-batch orders cannot keep up". After using the multi-functional laser system:

Misconception 1: Thinking that multi-functional equipment is "jack of all trades, master of none"

Many enterprises worry that multi-functional equipment will sacrifice the performance of a single function, but the LM-1390-WFC adopts a dual laser system design. Metal processing uses 1500W fiber laser, which is equivalent to the performance of special metal laser cutting machines; non-metal processing is equipped with 130W CO2 laser to meet the processing needs of most non-metallic materials. Actual test data shows that the metal cutting accuracy and speed differ from those of single-function equipment with the same power by no more than 5%, which can fully meet the needs of small and medium-batch production.

Misconception 2: Ignoring the Compatibility and Expandability of Equipment

Some enterprises only focus on current needs and ignore future development. When selecting a multi-functional laser system, it is necessary to pay attention to whether the equipment supports power upgrade and function expansion. The LM-1390-WFC reserves a power upgrade interface, and the fiber laser power can be upgraded from 1500W to 2000W and the CO2 laser power from 130W to 150W according to production needs in the later stage, without replacing the whole machine, reducing the cost of secondary investment.

Misconception 3: Only Looking at the Price but Ignoring After-sales and Consumable Costs

Low-cost multi-functional equipment may have potential quality hazards in core components, with frequent replacement of subsequent consumables and high maintenance costs. As a 12-year laser equipment manufacturer, Jinan LaserMen CNC has a professional after-sales team and a stable consumable supply system. The core components of the equipment are guaranteed for 1 year, with service outlets in many regions across the country and 24-hour response to maintenance needs. Its consumable prices are transparent and have a long service life, and the long-term use cost is about 30% lower than that of equipment from small manufacturers.

Return to Table of Contents1: Accuracy deviation occurs when switching between metal and non-metal processing

Cause: The optical path calibration in the two processing modes is not in place, or there is dust accumulation on the guide rail;

Solution: Before switching processing modes each time, use the calibration function of the equipment to calibrate the optical path; regularly clean the dust on the guide rail and keep the guide rail lubricated; if the deviation is large, contact the after-sales engineer for professional debugging.

2: Welds that end up spattered or weak during metal welding.

Cause: The wire feeding speed does not match the laser power, or the workpiece surface has oil stains and rust that are not cleaned up;

Solution: Select the corresponding welding parameters (wire feeding speed, laser power, welding speed) in the control system according to the thickness and material of the workpiece; clean the workpiece surface with the derusting function of the equipment before welding to ensure no impurities; if the problem persists, check whether the wire feeder is blocked and clean or replace the welding wire in time.

3: Burnt edges or uneven cuts during non-metal cutting

Cause: Excessively high laser power, too slow cutting speed, or improper auxiliary gas pressure;

Solution: Reduce laser power and increase cutting speed; adjust the auxiliary gas pressure according to the material type (air assist is recommended for acrylic cutting, oxygen assist is recommended for wood materials); for thick plates, adopt layered cutting to avoid burnt edges.

4: Alarm and shutdown during equipment operation

Cause: Unstable power supply voltage, cooling system failure, or errors in processing files;

Solution: Check whether the workshop voltage meets the equipment requirements (220V±10%) and equip with a voltage stabilizer; check the water level and water temperature of the cooling water tank to ensure the normal operation of the cooling system; troubleshoot whether there are path errors in the processing file, and re-generate the processing file before running.

Return to Table of ContentsDaily Maintenance: Clean up waste and dust on the workbench; check whether the laser head has stains and wipe it with a special cleaning cloth; check the water level of the cooling water tank and replenish distilled water in time when it is insufficient;

Weekly Maintenance: Clean the guide rail and lead screw, apply special lubricating oil; check the connection part of the laser tube and optical fiber to ensure no looseness; clean the air filter to ensure unobstructed auxiliary gas;

Monthly Maintenance: Calibrate the laser optical path to ensure processing accuracy; check the welding wire allowance and wire feeding smoothness of the wire feeder; back up equipment parameters to prevent parameter loss;

Annual Maintenance: Comprehensive overhaul and replace aging consumables (such as laser tubes, lenses); check the wiring of the electrical system to eliminate potential safety hazards.

Return to Table of ContentsThe following 5 questions help you quickly judge whether this 10-in-1 multi-functional laser processing system matches your production needs:

If you answer "Yes" to 3 or more of the above questions, this 10-in-1 multi-functional laser processing system is most likely suitable for your enterprise.

Return to Table of ContentsJinan LaserMen CNC has a professional R&D team that can customize equipment according to the special needs of enterprises. If your processing scenario has the following special requirements, you can contact the technical consultant to obtain an exclusive customization plan:

Address: No.13908, Hehua Road, Licheng District, Jinan City Shandong Province, China

Email: support@lasermencnc.com

Tel: +86-531-6781-2013

Jinan LaserMen CNC Equipment Co.,Ltd

No.13908, Hehua Road, Licheng District, Jinan City

Shandong Province, China 250100

Tel: +86-531-6781-2013

Mobile, WhatsApp, WeChat, Telegram, BOTIM: +86-15508686690

Copyright © 2019 Jinan LaserMen CNC Equipment Co. Ltd. All Rights Reserved