Posted on January 17th, 2026 · By Lasermencnc · In Laser Machines Blog · 5 Min Read

"Whenever I got mixed orders with metal letters and acrylic panels before, I had to outsource the acrylic processing, which would take 3 to 5 days. I had to pay high outsourcing fees, deal with constant customer rush orders, and my profit margins kept shrinking. Now with the Lasermencnc LM-1390-WFC Multi-functional Laser Processing Center, one machine handles everything perfectly. I can finish mixed material orders the same day, and my customer repeat purchase rate has increased by 25% directly!" Said Mr. Michael, who has been running a professional sign and advertisement shop for 12 years, glowing with excitement when talking about the great changes in his workshop recently.

For more detailed product information, please visit our official website: https://www.lasermencnc.com/multi-functional-laser-system/

Mr. Michael’s experience is a common pain point for countless sign shop owners worldwide. In the sign and advertisement manufacturing industry, orders for metal channel letters, acrylic display boards and custom engraved decorative products account for more than 60% of total business. Most of these orders require combined metal and non-metal processing. With traditional production methods, shop owners have to invest in metal cutting equipment separately, then outsource all acrylic processing to third-party factories. This not only lengthens the delivery cycle significantly, but also brings extra troubles such as outsourcing costs, logistics damage and communication errors, which all cut into the final profits sharply.

Mr. Michael did the math clearly: he spent as much as $80,000 to $100,000 on acrylic outsourcing fees alone each year. What’s worse, many long-term customers were lost just because of delayed delivery, which was a great pity for him.

He first came across the Lasermencnc LM-1390-WFC Multi-functional Laser Processing Center at an industry exhibition. After watching the on-site demonstrations of stainless steel letter cutting and acrylic engraving with perfect finished effects, he made an immediate decision to invest in this machine. Today, this laser machine has become the core production equipment in his workshop and completely transformed his business model.

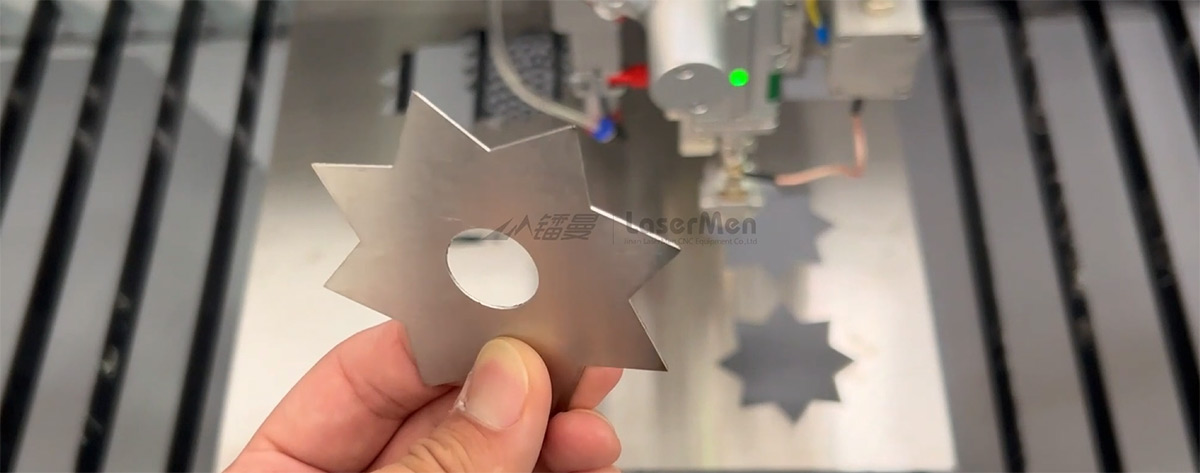

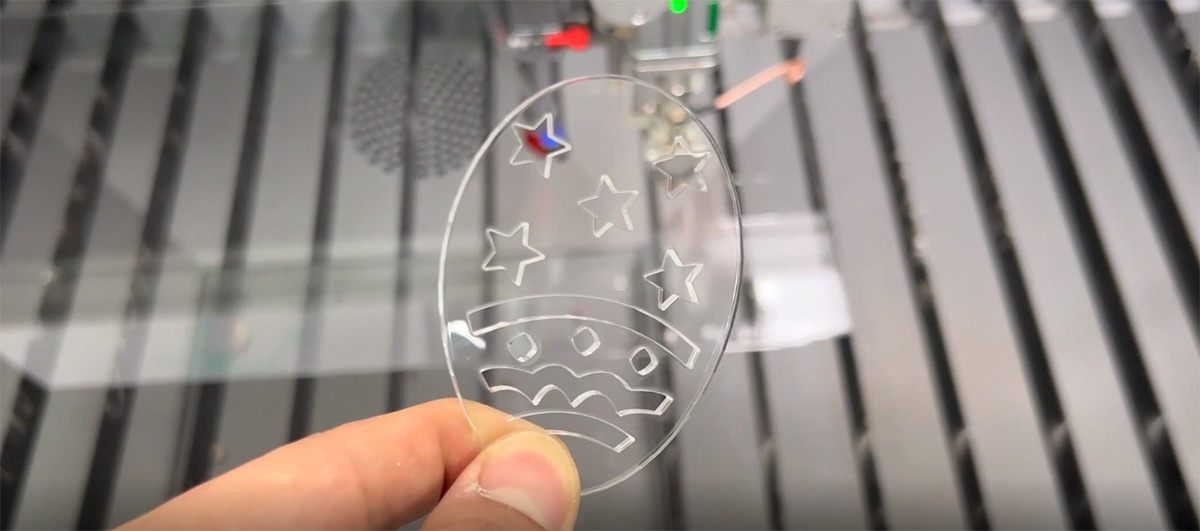

The core reason why the LM-1390-WFC has become a profit-making powerhouse for sign and advertisement shops is its powerful all-round processing capability that fully covers both metal and non-metal materials. Tailored for the high-frequency processing needs of the sign industry, it is equipped with a 1500W air-cooled fiber laser and a 130W CO2 laser. It can cut stainless steel with a thickness range of 0.5-4mm (optimal for ≤3mm), producing smooth, burr-free cut edges with no need for secondary polishing. For acrylic processing, it can cut up to 30mm thick plates, with an optimal cutting speed of 25mm/s for 3mm acrylic sheets, delivering ripple-free and scorch-free cutting surfaces that eliminate polishing and finishing procedures entirely.

Best of all, the LM-1390-WFC supports one-click fast switching between fiber laser and CO2 laser systems with no complicated parameter adjustments required. Ordinary staff in Mr. Michael’s shop mastered the whole operation after just one day of simple training. No need to hire expensive professional technicians, and production efficiency has been greatly improved at the same time.

For sign shop owners, fast delivery speed and premium processing quality are always top priorities, and the LM-1390-WFC backs this up with solid hard data. Take a common mixed order of 1m×0.5m stainless steel channel letters with acrylic back panels as an example: traditional production with in-house metal cutting plus outsourced acrylic processing would take 3 to 5 days. With the LM-1390-WFC, one-stop completion of metal cutting and acrylic engraving is achievable, and the whole production process from design file import to finished product output only takes 4 hours, increasing delivery efficiency by more than 5 times.

Boasting a repeat positioning accuracy of ±0.03mm, the LM-1390-WFC ensures the dimensional error of mass-produced sign letters is less than 0.1mm, with sharp and delicate engraved patterns. Customer satisfaction has been raised to a new level, and the repeat purchase rate of Mr. Michael’s shop has jumped from 45% to an impressive 70%.

The LM-1390-WFC is also highly recognized by shop owners for its ease of use and outstanding cost performance. Adopting plug-in wiring design, it can be installed and used immediately without professional technicians. Equipped with universal casters and adjustable floor feet, it can be easily moved by a single person. With a compact footprint of only 2380×1700×1100mm, it fits perfectly even in small workshops with limited space.

From a cost perspective, one LM-1390-WFC is equivalent to owning three separate machines: a metal laser cutter, a non-metal laser engraver and a laser welder. The initial investment is $120,000 less than purchasing these three devices separately. Combined with the annual outsourcing cost savings of $80,000 to $100,000, the equipment cost can be fully recovered in less than one year.

What’s more noteworthy is the LM-1390-WFC’s dual-system design (air-cooled handheld laser + fixed bed laser system), which ensures stable production and avoids costly downtime caused by single-system failure. With global after-sales support, including 8-hour quick phone response and professional engineer on-site maintenance service, Mr. Michael never worries about equipment maintenance issues.

"In the past, when outsourcing processing, I had to rework products if there were size deviations, with no room for timely adjustments. Now I handle all production in-house, I can make real-time revisions whenever needed. Coupled with the stable performance of the LM-1390-WFC with almost no breakdowns, we have had zero production errors for the past six months." Mr. Michael added.

Today, relying on the core advantages of fast delivery and high-quality craftsmanship, Mr. Michael’s sign shop has firmly established its leading position in the local market. Not only has the repeat purchase rate of regular customers been rising steadily, but he has also attracted a large number of bulk orders from neighboring cities and regions.

"My competitors are still struggling with outsourcing troubles and delivery delays, while we have seized the market opportunity with efficiency and quality." Mr. Michael’s confidence all comes from the core competitiveness brought by the Lasermencnc LM-1390-WFC.

For sign and advertisement shop owners looking to break through business bottlenecks and increase profits, the Lasermencnc LM-1390-WFC Multi-functional Laser Processing Center is more than just a processing machine. It is a profit engine that expands business boundaries, reduces operating costs and improves customer satisfaction.

Whether it is stainless steel letter cutting, acrylic engraving, or custom mixed material orders, the LM-1390-WFC delivers an all-round performance of "one machine replaces three", making sign and advertisement production more efficient, more worry-free and more profitable. Say goodbye to outsourcing delays and profit loss, choose the LM-1390-WFC, and unlock new growth potential for your sign business!

Jinan LaserMen CNC Equipment Co.,Ltd

No.13908, Hehua Road, Licheng District, Jinan City

Shandong Province, China 250100

Tel: +86-531-6781-2013

Mobile, WhatsApp, WeChat, Telegram, BOTIM: +86-15508686690

Copyright © 2019 Jinan LaserMen CNC Equipment Co. Ltd. All Rights Reserved