① Adjust each anchor bolt one by one to ensure the bolts bear force evenly on the whole with no obvious unbalance of the machine.

② Place the level bracket on the tool slot and mount the spirit level on it.

③ Divide the horizontal and vertical travel strokes into three equal sections respectively, with the front, middle and rear positions as the observation points.

④ Move the carriage, observe the spirit level readings at the front, middle and rear observation points, and carefully adjust each anchor bolt one by one.

⑤ Repeat the above steps until the level readings meet the specified requirements.

⑥ Tighten all anchor bolts securely.

Note to users: The levelness of the equipment may change with prolonged service time, so it is recommended that users conduct a level recheck at least once a year.

In addition, if a major incident such as external impact on the equipment occurs during operation, users must recheck the machine level.

Please pay attention to personal safety during the installation and fixation of the equipment, and avoid any damage to the equipment in the process. Contact our company in a timely manner if any problems arise.

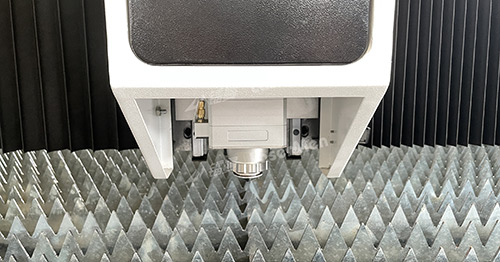

Position the machine in a suitable installation area, adjust it to be parallel and lower it slowly, ensuring that all anchor bolts touch the ground completely at the same time.

If you're looking to purchase a laser cutting machine recently, I'd like to recommend several models to you. They've received excellent feedback from users, and we hope they can support your business endeavors. Please click the link below:

https://www.lasermencnc.com/list_15_1.html