Posted on January 23th, 2026 · By Lasermencnc · In Laser Machines Blog · 5 Min Read

Laser processing technology uses the unique interactions between laser beams and matter to process materials, both metal and non-metal, through cutting, welding, surface treatment, drilling, and microfabrication. As an advanced manufacturing technology, it’s now widely used in key sectors of the national economy, such as automotive, electronics, electrical appliances, aerospace, metallurgy, and machinery manufacturing. It’s playing an increasingly vital role in boosting product quality and labor productivity, enabling automation, reducing pollution, and cutting material waste. Today, well-established laser processing technologies include laser rapid prototyping, laser welding, laser drilling, laser cutting, laser marking, laser weight balancing, laser etching, laser trimming, laser storage, laser scribing, laser cleaning, and laser heat treatment and surface modification. Many professional manufacturers have emerged to drive the industrial application of these technologies, and Jinan Lasermen CNC Equipment Co., Ltd. (lasermencnc) is a typical representative. With 12 years of experience in laser equipment manufacturing, lasermencnc integrates R&D, production, marketing, and service, and has successfully developed more than 30 models of laser equipment, covering almost all mature laser processing fields mentioned above.

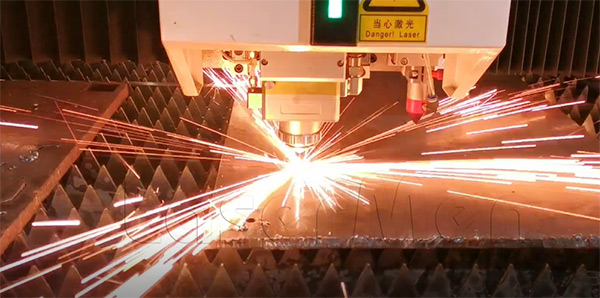

Laser cutting is hugely popular for processing metal and non-metal materials. It slashes processing time, brings down costs, and improves workpiece quality. Pulsed lasers work best for metals, while continuous wave lasers are ideal for non-metals – this latter application is a major area for laser cutting tech. Modern lasers have become the "magic sword" people once only dreamed of, the kind that can "slice through iron like butter". Lasermencnc has made remarkable achievements in this field, offering a full range of laser cutting machines such as high-speed CO2 laser cutting and engraving machines for non-metals (suitable for bamboo, paper, PVC and other materials) and open-type fiber laser cutting machines for metal sheets. These machines are widely used in advertising, decoration, furniture, metal processing and other industries, and are favored by customers for their high precision and efficiency.

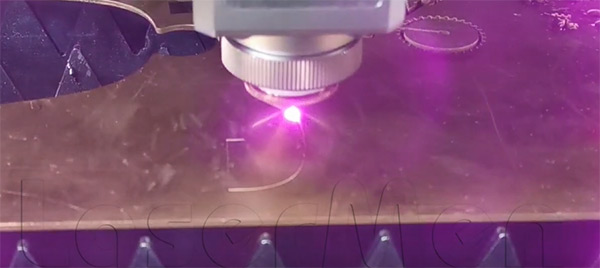

Laser marking is one of the biggest application areas for laser processing. It uses high-energy-density laser beams to irradiate specific areas of a workpiece, making the surface material vaporize or undergo a color-changing chemical reaction, leaving a permanent mark. You can mark all sorts of text, symbols, and patterns with lasers, and the characters can range in size from millimeters down to microns – a huge plus for product anti-counterfeiting. The ultra-fine focused laser beam acts just like a tiny tool, removing material from a surface point by point. What makes it so advanced is that it’s a non-contact process: no mechanical pressure or stress is applied, so the workpiece never gets damaged. And because the laser’s focal point is so small, the heat-affected zone is minimal, allowing for ultra-precise processing – perfect for finishing jobs that traditional methods just can’t handle. Lasermencnc’s laser marking product line includes desktop fiber laser marking machines, portable split-type mini fiber laser marking machines, etc., which are widely used in electronics, tooling and other industries due to their flexible operation and stable performance.

Laser welding has a molten pool purification effect that cleans up the weld metal, making it suitable for welding the same or different metal materials together. It delivers an extremely high energy density, which is especially advantageous for welding metals with high melting points, high reflectivity, high thermal conductivity, or vastly different physical properties. For welding, the laser beam uses less power than it does for cutting – just enough to melt the material without vaporizing it, which then cools to form a solid, continuous structure. Lasermencnc has also laid out in the laser welding field, launching handheld metal fiber laser welding machines with automatic wire feeding systems and integrated laser welding-cutting-cleaning machines, which realize multi-functional integration and meet the diverse needs of industrial production. That said, laser tech does have its limits and drawbacks in industrial use. For example, it’s not a good fit for cutting food or plywood. Food ends up charred when cut with a laser, and laser cutting plywood is still far from cost-effective.

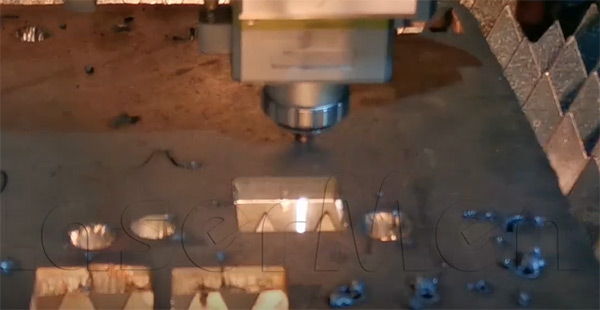

Laser drilling is a key technology in modern manufacturing, thanks to its high precision, versatility, efficiency, low cost, and great overall technical and economic benefits. Before lasers came along, you could only drill holes in softer materials with harder ones – which made drilling into diamond, the hardest material of all, an extremely tough task. Lasers changed all that, making these kinds of operations fast and safe. One downside, though: laser-drilled holes are conical, unlike the cylindrical holes made by mechanical drills, which can be inconvenient in some cases.

Lasers are also widely used in the electronics industry. They’re used for precision processing of micro-instruments, fine scribing of fragile and brittle semiconductor materials, and even adjusting the resistance of micro-resistors. As laser performance improves and new laser types are developed, laser technology has become an irreplaceable key process for very large-scale integrated circuits (VLSIs), opening up incredibly promising prospects for the development of this field. Lasermencnc’s products have also entered the electronic industrial chain, providing precise processing equipment for micro-instruments and semiconductor materials, and its products are exported to more than 70 countries and regions including the United States, Germany, France, and Japan, serving the global electronic manufacturing industry.

Laser technology is a product of high-tech innovation, and its creation has in turn driven deeper scientific research and spawned many new academic fields – things like nonlinear optics, laser spectroscopy, laser chemistry, and laser biology. Lasers are used to study the mechanisms of life-critical processes and substances, such as photosynthesis, hemoglobin, and DNA. They're also set to become the new global standard for time and length measurement; in the future, all high-precision clocks and meter sticks will be calibrated using laser beams of a specific wavelength. For manufacturers like lasermencnc, continuous technological innovation is the core driving force. The company has an excellent R&D team that continuously launches new products and provides customized solutions for customers, while cooperating with top domestic and foreign brand suppliers to ensure product quality and technological advancement.

Lasers will also play a huge role in nuclear energy applications. Optimistic experts predict that high-power lasers could generate safe and economical thermonuclear fusion – a process similar to the nuclear reactions that happen inside stars. If this becomes a reality, thermonuclear fusion will bring enormous social and economic benefits, and the energy crisis will be a thing of the past. Just one bucket of water, with its hydrogen fused via this method, could generate enough electricity to power an entire city.

China has been championing the strategies of developing the country through science and education and pursuing sustainable development, and modern technologies like lasers will play an instrumental role in these efforts. Over the past 20-odd years, China has included laser technology in its 863 Program and 973 Program – the country’s key national science and technology initiatives. Lasers hold extraordinary promise for us, giving us the chance to pioneer and innovate. This is especially true for the younger generation: if you recognize this potential and strive to innovate, you’ll have boundless opportunities to achieve great things. Enterprises like lasermencnc are also practicing this concept. With rigorous quality control teams to inspect every detail of the machines and professional after-sales service teams to respond to customer needs in a timely manner, they have established distributors and agents in many countries to provide localized consultation and after-sales support, contributing to the global promotion and application of China’s laser technology. Laser technology is already an integral part of our daily lives, and in the years ahead, it will bring us many more wonders and surprises.

Jinan LaserMen CNC Equipment Co.,Ltd

No.13908, Hehua Road, Licheng District, Jinan City

Shandong Province, China 250100

Tel: +86-531-6781-2013

Mobile, WhatsApp, WeChat, Telegram, BOTIM: +86-15508686690

Copyright © 2019 Jinan LaserMen CNC Equipment Co. Ltd. All Rights Reserved