In the field of laser processing equipment, it is often difficult to achieve both "multi-functionality" and "high precision and efficiency" - however, the newly launched LM-1390FC fiber optic CO2 hybrid cutting machine by LaserMen breaks through this industry pain point with its innovative dual-laser system and high-configuration design. It can accurately cut metal materials and efficiently process non-metallic workpieces, providing a "one-stop processing solution" for multiple industries such as advertising, furniture, and craft gifts.

The LM-1390FC weighs only 750 kg and occupies only 5.3 square meters, making it flexible enough to fit even in small to medium-sized workshops. Its 1.5-meter feed width, combined with detachable front and rear covers, supports "front and rear through-feed" processing of long materials, eliminating the need for segmentation and significantly reducing operational complexity. Its effective working area of 1.3 meters × 0.9 meters meets the needs of batch processing of sheet metal and is also suitable for the precision manufacturing of small to medium-sized workpieces, balancing practicality and space utilization.

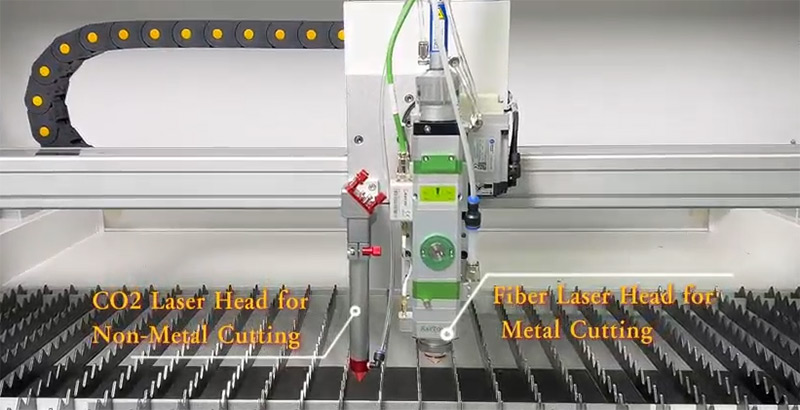

As a core highlight, the LM-1390FC features a dual system of fiber laser and CO₂ laser, precisely controlled by the Baichu control system, enabling "one machine to switch between dual processing modes":

Metal Cutting Capabilities: Centered on a 1500-watt fiber laser, it can easily cut 10mm thick carbon steel, stainless steel, aluminum plates, brass, galvanized plates, and other metal materials at high speeds, reaching a maximum cutting speed of 35 meters per minute, far exceeding similar equipment;

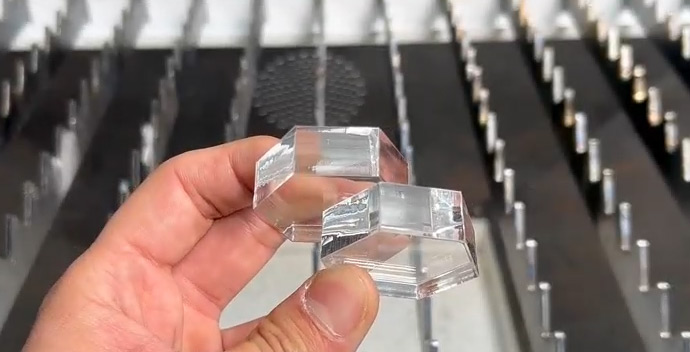

Non-metal Processing Advantages: An optional 130-watt or higher power CO₂ laser can be added for rapid cutting and fine engraving of non-metallic materials such as wood, acrylic, fabric, and leather, producing smooth, burr-free cuts without the need for secondary polishing;

Flexible Customization Options: For customers with only a single processing need, the equipment can also be customized into a "single-head mode"—a single fiber head dedicated to metal cutting, or a single CO₂ head specializing in non-metallic processing, reducing initial investment costs.

III. High-end configuration ensures both accuracy and stability online.

To ensure processing quality and long-term durability, the LM-1390FC has undergone rigorous upgrades in key components: High-precision transmission: The motion components utilize servo motors and high-speed module transmissions, controlling repeatability within ±0.01mm. This results in smoother lines when cutting complex shapes, making it particularly suitable for applications with stringent precision requirements, such as electronic components and advertising signs. Anti-scratch platform: The innovative grooved platform design reduces the contact area between the workpiece and the table surface, preventing secondary laser reflections. "Top-level rounded corner smoothing" provides stable support for the workpiece while preventing surface scratches. Stable control system: The industrial computer boasts strong anti-interference capabilities. Combined with a multi-angle adjustable rocker-arm computer control panel and wireless handle assistance, the system operates stably and offers flexible and convenient operation, allowing even beginners to quickly learn how to use it.

IV. Detailed Design: Balancing Safety and Long-Term Use

Beyond its core performance, the LM-1390FC demonstrates thoughtful attention to detail: the bottom funnel surface is covered with a 3mm thick carbon steel plate, forming a "double-layer protection" structure that effectively prevents "overheating" during processing and extends the funnel's lifespan; it eliminates the need for frequent replacement of the laser's working gas and adjustment of the optical path, resulting in lower daily maintenance costs; and its key components are highly durable, meeting the long-term continuous production needs of enterprises.

V. Multi-industry adaptability: An "all-around processing assistant" from advertising to furniture.

Leveraging its "metal + non-metal through-cutting" advantage, the LM-1390FC can be widely used in advertising signage production (stainless steel lettering cutting, acrylic engraving), furniture manufacturing (wood board cutting, leather carving), arts and crafts gift processing (precision cutting of metal ornaments, carving of wooden figurines), and apparel and home textiles (fabric cutting). One machine can replace multiple traditional processing machines, helping businesses save on equipment investment, optimize production processes, and truly achieve "cost reduction and efficiency improvement."

From its compact body to its dual-laser core, from high-precision control to multi-scenario adaptability, the Laserman LM-1390FC fiber optic CO2 hybrid cutting machine is not only a laser processing device but also a "smart production partner" that helps businesses enhance their competitiveness. Whether it's a small or medium-sized processing shop or a large-scale production enterprise, everyone can unlock a more efficient and precise processing experience with this "dual-function" machine.